-

Color card

Aluminum plastic plate, also known as aluminum plastic composite plate, is a new type of material composed of aluminum plate treated and coated with baking paint as the surface, polyethylene and polypropylene plastic mixed as the core layer, and composite through a series of processes. Due to different usage environments and user requests, there are various types of color cards available: sparkling bead series, monochrome series, high gloss series, mirror series, wood grain series, stone grain series, brushed grain series, etc.

More +

-

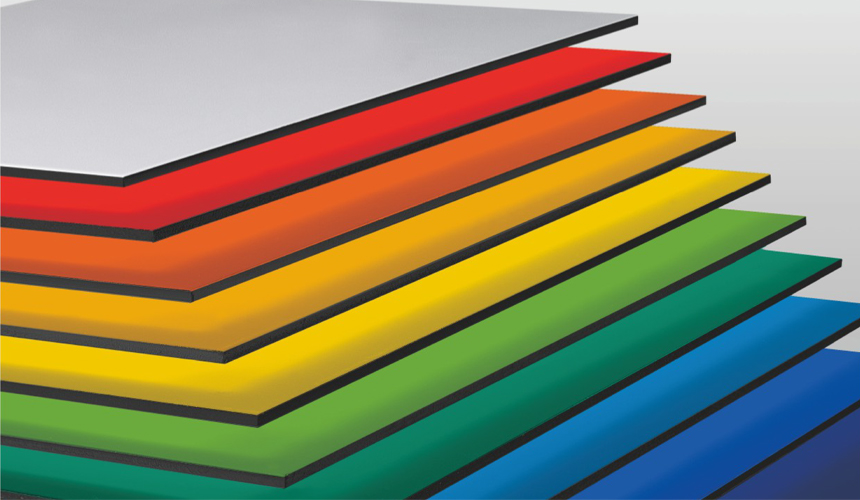

Aluminum plastic

The series of aluminum plastic panels produced by Shanghai Jixiang Building Materials Group include brands such as ZWM, Jixiang Jiamei, Jixiang Four Seasons, Shenzhou Jixiang, Jinmu, and Xiqing. The aluminum plastic panel series is divided into five categories: interior wall panels, exterior wall panels, wood grain panels, granite grain panels, and fire resistant panels, with over a hundred different specifications and colors of panels. The Baoyi aluminum plastic plate series uses high-quality rust resistant alloy plates and high-strength polyethylene core plates. The coating used is currently advanced fluorocarbon resin coating, which is completely produced according to relatively standard processes.

More +

-

Aluminum veneer

Aluminum veneer has the advantages of light weight, high strength, waterproofing, anti fouling, fire prevention, corrosion resistance, good processing performance, low maintenance costs, and long service life. It can be processed into curved or irregular shapes, and the surface can be sprayed into various colors to form various beautiful patterns on the wall. It can also be combined with glass curtain walls to form different exterior shapes, making the building more noble and elegant in style. It is suitable for decoration of interior and exterior walls of various buildings, lobby facades, column decorations, elevated corridors, Skyway, elevator edging, balcony packaging, advertising signs, indoor profiled ceiling, etc.

More +

-

Honeycomb board

Aluminum honeycomb board is a honeycomb sandwich structure board made of high-strength alloy aluminum board with good weather resistance treated by fluorocarbon spraying as the surface, bottom plate, and aluminum honeycomb core in the middle, which is compounded by high temperature and high pressure. It has the characteristics of light weight, high strength, good rigidity, sound insulation, and heat insulation. Aluminum honeycomb panels are aerospace materials that have gradually developed and applied in the civilian field. Other industries such as construction, transportation, billboards, etc.

More +

-

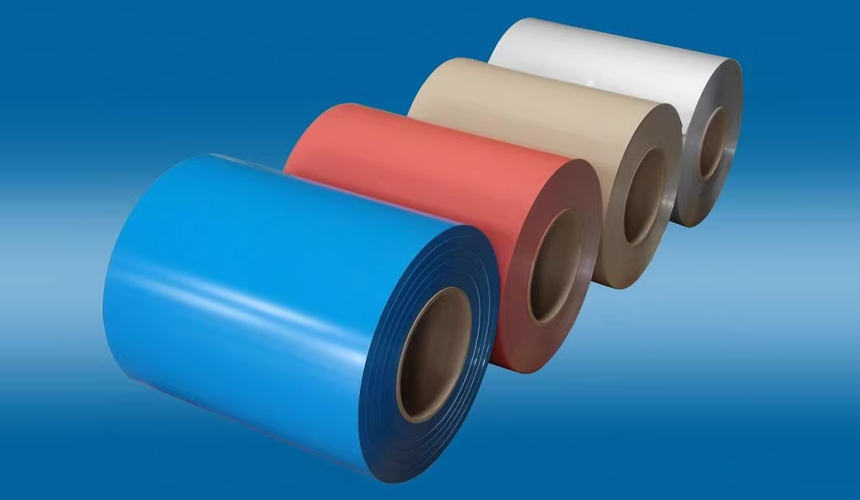

Aluminum Coil

Our company uses high-quality aluminum foil as the base material for color coated aluminum coils, introduces high-tech technology, cooperates with high-performance roller coating processing technology, and combines current advanced production technology to effectively control the accuracy and flatness of the board, with uniform color and bright luster. The product has excellent processing performance, durability, acid resistance, alkali resistance, corrosion resistance, powdering resistance, decay resistance, UV radiation resistance, friction resistance, and other characteristics.

More +

-

Silicone

This product is a widely used and durable acidic adhesive used for glass sealing and building materials. The product is suitable for assembly of glass, aluminum alloy, ceramics, fiberglass, plastic steel, non oil wood, etc. Powder sprayed aluminum alloy must be thoroughly cleaned of the wax coating with a solvent.

More +

-

Aluminum profile

Aluminum square tube is a lightweight, corrosion-resistant, and easy to process building decoration material, which has been widely used in indoor and outdoor decoration. Its rich colors and diverse types can meet different decorative needs. During installation and use, attention should be paid to safety and stability, and regular cleaning and maintenance should be carried out. The advantages and application scenarios of aluminum square fittings make them an indispensable part of the modern architectural decoration field.

More +