Durability

Fluorocarbon coated aluminum plastic panels have good durability, weather resistance, high temperature resistance, wear resistance, and pollution resistance.

Economy

Aluminum plastic panels use various high-quality coatings without the need for long-term maintenance, which eliminates the cost of maintenance and upkeep for high-rise and large buildings. Urban pollution in China is severe and requires maintenance and cleaning after a few years of use. Due to its good self-cleaning performance, only neutral cleaning agents and water are needed to make the panels look new after cleaning.

Durability

Fluorocarbon coated aluminum plastic panels have good durability, weather resistance, high temperature resistance, wear resistance, and pollution resistance.

Flatness

Aluminum plastic panels provide excellent flat surfaces, meeting the pursuit of high aesthetics in modern architecture.

Lightness

Aluminum plastic board is made of aluminum alloy and high-quality plastic composite, which is lighter in weight than other decorative materials, reducing the weight burden of the material itself, facilitating construction, and greatly shortening the construction period.

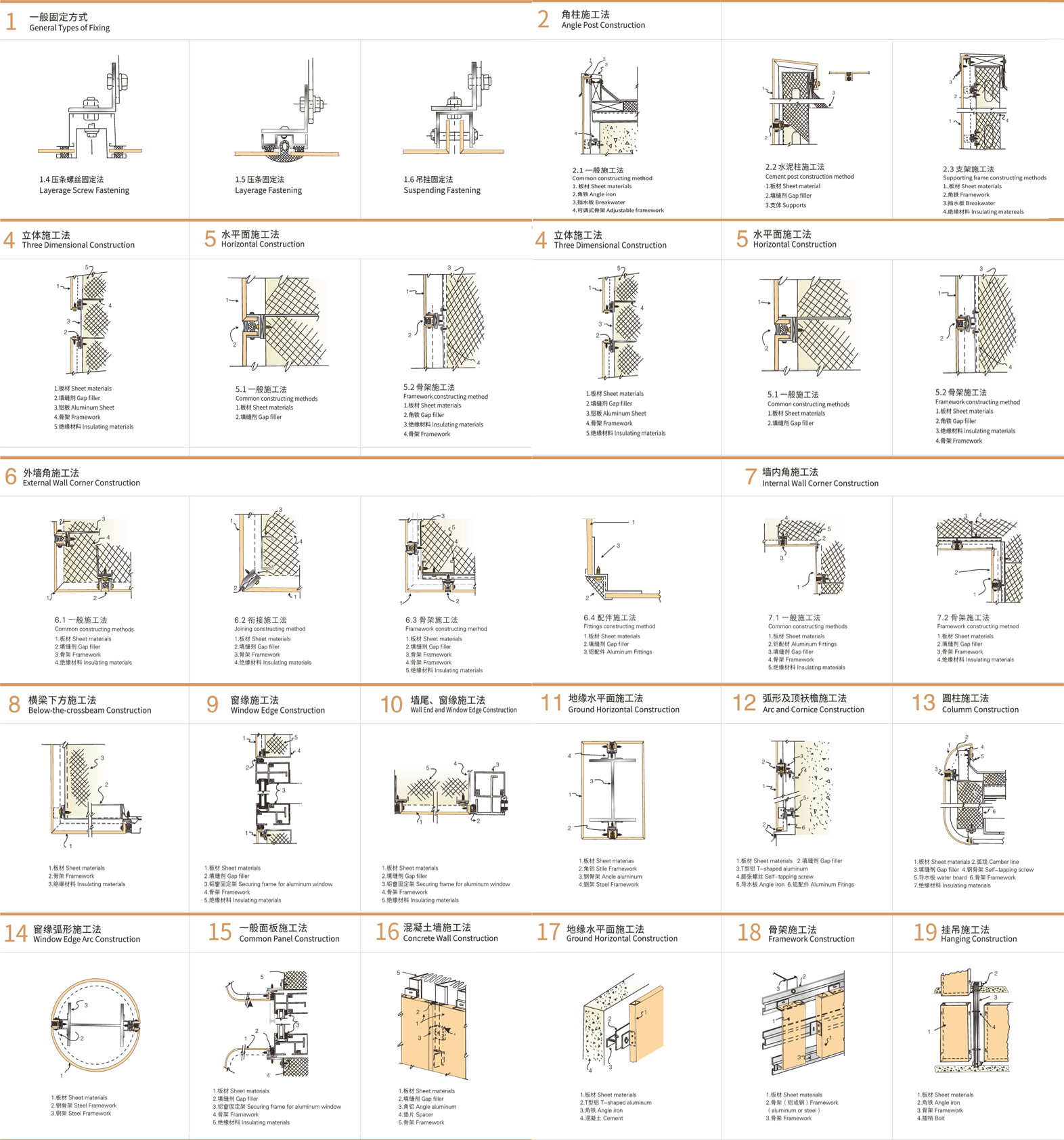

Constructability

Aluminum plastic panels are easy to cut, cut, gouge, bend into arcs, right angles, and other shapes, which can fully cooperate with decoration and design various shape changes.

Fire resistance

The non combustible outer aluminum sheet of aluminum plastic plate can protect the polyethylene core material and block heat conduction in the early stage of combustion, achieving advanced fire resistance.

Design performance

Aluminum plastic panels can produce unique colors and shapes according to customer requirements, meeting the unique design of designers and achieving perfect decorative effects.

Environmentally

The surface layer does not change and has no pollution to the environment.

Aluminum plastic board is a good material that is easy to process, shape, and assemble, and is also an excellent product for pursuing efficiency and fighting for time. It can shorten the construction period and reduce costs. The equipment of a typical sheet metal or woodworking factory can easily complete its processing and assembly work.

Aluminum plastic panels can:

1. Cutting, cutting, slotting, band saw, vertical saw, locking hole, machining countersink.

2. Cold bending, cold folding, cold rolling.

3. Riveting, screw bonding, welding, clamping or bonding.

4. Spray painting, screen printing, sign boards, and advertising sign boards.

• Curtain wall decoration/interior decoration/ airports/docks/stations/subways/shopping malls/hotels/hotels/entertainment venues/high-end residences/villas/office buildings

• Large advertising signs/display windows/roadside newspaper booths/book stalls/telephone booths/traffic guard booths/roadside gas stations

• Indoor walls/ceilings/compartments/kitchens/bathrooms/wall skirting

• Shop decoration/interior shelves/cabinets/pillars/furniture/train/car/ship/passenger car decoration

• Renovation and renovation of old buildings

• Purification and dust prevention engineering

innovation driven

Building a Competitive Building Materials Group